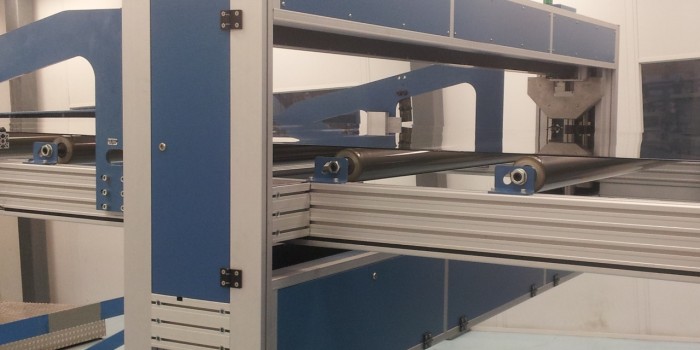

Sheet Thickness Analyzer

The Sheet Thickness Analyzer is a fully automatic, scanning thickness inspection system for solid and foamed sheet manufacturers with any thickness. Based on optics, the system is capable of accurately measuring all sheet thicknesses without emitting Gamma, Beta or X-ray radiation.

Quicker Setups

The system automatically scans the thickness of the entire width of the sheet. After each scan, the software produces a graph and report of the sheet thickness that corresponds to each of the die screws and heat zones. The results show the operator which screws or heat zones to adjust to bring the sheet thickness in to the specified tolerances.

Cost Savings

Zero-radiation measurement

thicknesses.

Quicker Setups

The system automatically scans the thickness of the entire width of the sheet. After each scan, the software produces a graph and report of the sheet thickness that corresponds to each of the die screws and heat zones. The results show the operator which screws or heat zones to adjust to bring the sheet thickness in to the specified tolerances.

Cost Savings

Zero-radiation measurement

thicknesses.

Automation

Cost savings

Documentation

Safety

Automation

Cost savings

Documentation

Safety

Advantages

Cost savings

Significant savings in raw material, lost production time and scrap.

Quality

Higher overall product quality due to more even material distribution.

Improved yield

Significantly shorter setup and changeover times.

Safety

The optics-based system doesn’t emit radiation like Gamma back-scattering, Beta or X-ray.